Bits designed to drill metal have flutes that taper to a point at either a 118- or 135-degree angle. End Mill Adaptor Morse Taper Style B Draw Bar.

Taper Shank Drill Bit 138 Degree 10 Mm Straight Shank Drill Bit 138 Degree 5 Mm 3d Cad Model Library Grabcad

Different shank and chuck.

. Part of the drill between neck and tang is known as Shank. HSSs are types of strong steels that contain elements such as chromium molybdenum carbon and tungstenA tapered drill bit made out of HSS is very hard and resistant to corrosion abrasion and high temperatures. The original thinning shape 3-rake improves centripedality and chip separation.

In many cases a general-purpose arrangement is used such as a bit with cylindrical shaft and shank in a three-jaw chuck which grips a cylindrical shank tightly. For technical drawings and 3-D models click on a part number. Also known as A-taper bits.

The shank for these drills conforms to Morse tapers. Subscribe to my channel. Nachi-Fujikoshi Taper Shank Drill Bits HSS A general-purpose drill used in the widest ranges of applications.

ARAL - Straight Turning. Install the Morse taper shank directly into the tapered spindle on machines such as drill presses and lathes. HS Taper Shank Core Drill Three Flute.

The diameter varies from 15 to 26 mm increasing by 03 mm in lower series to 025 mm in higher series. On the taper shank is the another term is used which is called tang. The drill shank taper is 1 in 6 and the drill is secured by a screw thread so the taper is there to provide good location not to drive the drill by friction.

The base metal high-speed steel is a material with metal components such as tungsten molybdenum and chrome added and has excellent abrasion resistance and toughness. A standard drill that corresponds to the JIS standard. Made from solid carbide these drill reamers are strong and heat resistant.

For technical drawings and 3-D models click on a part number. The base metal high-speed steel is a material with metal components such as tungsten molybdenum and chrome added and has excellent abrasion resistance and toughness. 8 rows Tapered-Round-Shank Masonry Drill Bits for Rotary Hammers.

Also known as A-taper bits these fit rotary hammers with a taper-shank chuck. For example one of the most common sizes of taper used on drill presses found in the home shop is the 2 MT or 2 Morse taper. The tapered tip gradually pierces your material to reduce friction and the straight flutes make clean cuts without chipping or peeling the edge of the hole.

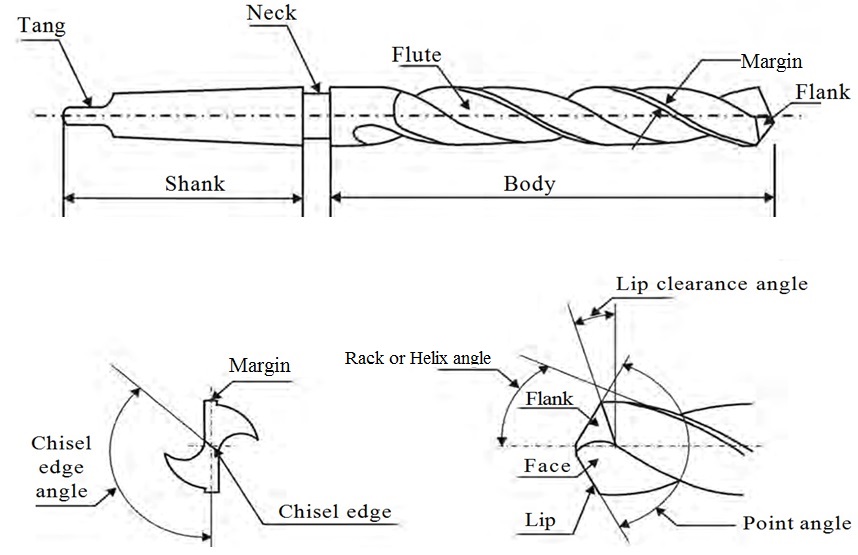

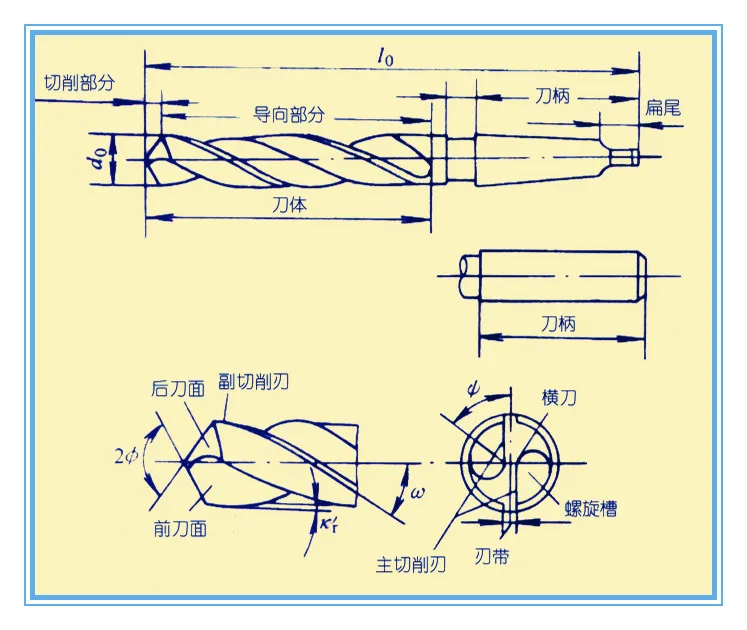

Carbide Tipped Tool Bits Left Hand. Drill NomenclatureDrill Nomenclature Cutting Diameter. Morse Taper Style A Tanged End Mill Holder.

The drills have two helical flutes with a tapered shank for holding and driving the drill. Drills and lathes use taper shank drill bits and arbors. Bits with a 118-degree point are general-purpose bits while those with a 135-degree point are self-cleaning which means they shed shards of metal instead of allowing them to accumulate around the shank.

The next most common size is the 3 MT found. At times the female Morse Taper cavity in a machine may be slightly smaller than the maximum diameters shown above. Get 10 free Shutterstock images - PICK10FREE.

Taper Shank Drills HSS A taper shank drill high-speed steel is a cutting tool that is attached to a drill press a milling machine a lathe etc. The cutting edges of the drill bit contact the workpiece and are connected via the shaft with the shank which fits into the chuck. This is because the MT tooling often extends a bit past the end of the spindle that is receiving the Morse Taper Tool.

Tapered shank drills have self-holding tapes that fit directly into the drill press spindle. Drill and finish holes in a single pass with these dual-purpose tools. It is the portion between the point and the.

Taper shank drills and accessories come in a series of standard sizes and these are each given a number designation. Usually the size of a drill bit is punched at the shankfor example ¼ inch ½ inch etc. Taper Shank Twist Drill.

Straight shank twist drills are usually l2-inch or smaller and tit into geared drill chucks while tapered shank drills are usually for the larger drills that need more strength which is provided by the taper socket chucks. Drill holes using simultaneous rotary and hammering action to break masonry material into tiny granules. As straight shank or tapered shank Figure 4-7.

Taper shank is also known as Tang. Many types of drill bits including tapered drill bits are constructed out of high-speed steels HSS. HS Taper Shank Core Drill Four Flute.

And used to drill holes. The shank is the end of a drill bit grasped by the chuck of a drill. Largest diameter measured across the top of the lands behind the point Back Taper The diameter reduces slightly toward the shank end of the drill this is known as back taper.

122 rows Tapered squareround-shank drill bits have a tapered square shank that can be cut off to expose a round shank. A tapered shank is a self-holding that can fit directly into the drill press spindle. 58 2MT 118 Point High Speed Steel Taper Shank Drill Bit Oxide Finish 4-78 Flute Length 8-34 OAL Spiral Flute Series 209 MSC 78528759 Precision Twist Drill 020040 In.

And used to drill holes. TC 9-524 Remove all chuck keys and wrenches before operating. It is not clear form the text whether it was Watt or Green who came up with the taper but a drawing by Watt dated 1811 shows a tapered shank spade drill in a tapered spindle.

Carbide Tipped Tool Bits MDX Brand. Taper Shank Drill Bits HSS A taper shank drill high-speed steel is a cutting tool that is attached to a drill press a milling machine a lathe etc. R8 End Mill Adapters.

This type of bit drills faster and penetrates material with less pressure than rotary-only bits. Masonry Drill Bits for Rotary Hammers. This fits into a slot in the spindles sleeve.

For Instance the A dimension for a MT2 female cavity. Taper type straight shank drill with a TiN coated surface. As there are many types of drill bits there is equal variance in drill bit shanksThe primary difference between the shanks is shape but they can also have functional distinctions.

A drill bit shank is the end piece of a drill that connects into the chuck of a spinning mandrelIn essence it is the male end of the bit that does not drill or mill. The diameter ranges from 3 to 100 mm. The figure illustrates the drill.

A split point keeps the bit centered without a pilot hole.

Twist Drill Nomenclature Learn And Grow

Morse Taper Shank Drills D115 D115 Drawing Jpg Sutton Tools

Straight Shank Taper Length Twist Drill Sizes

Taper Shank Drills Hss Misumi Indonesia

Twist Drill Parts Types And Twist Drill Nomenclature Pictures

Taper Shank Twist Drills ट पर श क ट व स ट ड र ल ट पर श क ट व स ट ड र ल V M Tools Co Mumbai Id 3501320073

Gratis Pengiriman 1 Pc 16 5 218mm Cnc Digiling Hss M2 Made Lancip Putar Bor Bits Untuk Berbagai Jenis Bahan Pekerjaan Pengeboran Drilling Technology Drilling Tiledrill Sharpner Aliexpress

Bor Putar Bilah Panjang Hss Khusus Buy Standar Hss Taper Shank Mata Bor Hss Sepenuhnya Tanah Twist Latihan Paralel Shank Series Twist Latihan Product On Alibaba Com

0 comments

Post a Comment